| 73.2% |

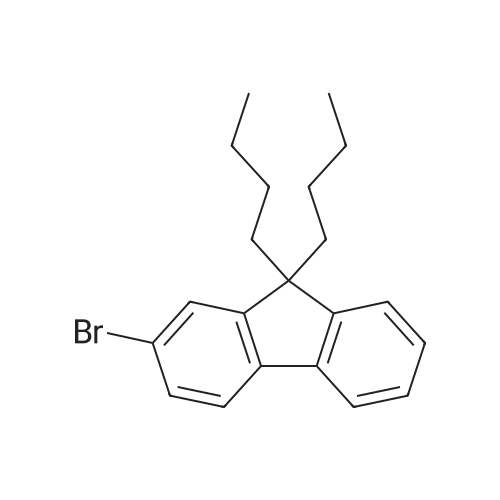

With tris-(dibenzylideneacetone)dipalladium(0); tri-tert-butyl phosphine; sodium t-butanolate In toluene for 48h; Inert atmosphere; Schlenk technique; Reflux; |

General procedure for the synthesis

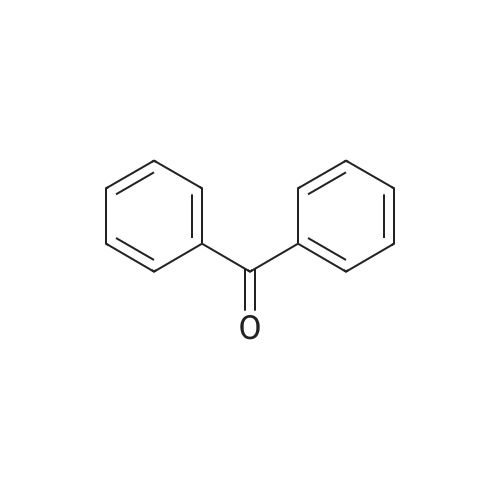

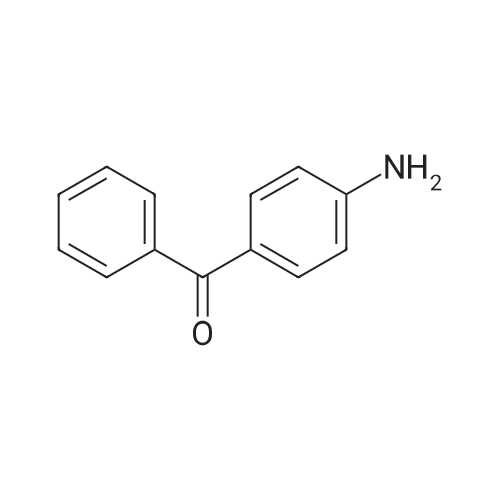

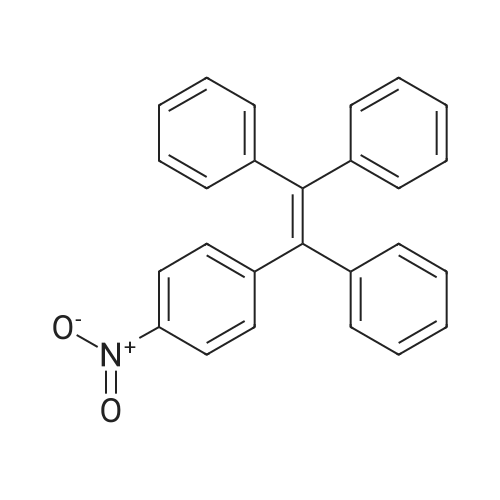

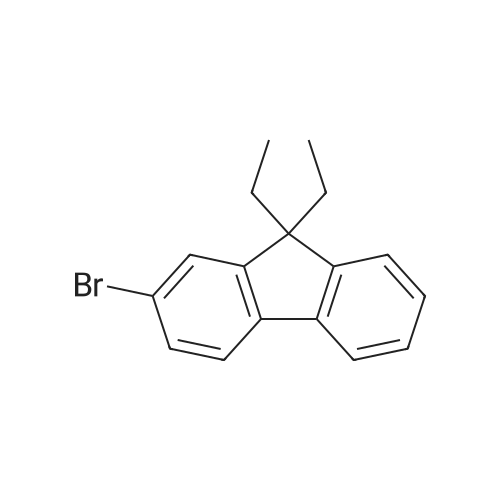

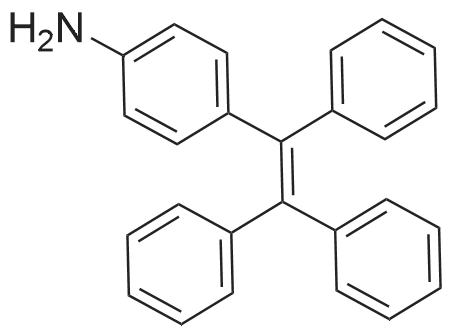

General procedure: Synthesis of compounds 1-3: A 50 mL two-necked round-bottom flask was evacuated under vacuum and then flushed with dry argon three times. Subsequently, compound I-1 (735.4 mg, 3.0 mmol) or I-2 (903.7 mg, 3.0 mmol) or I-3 (1072.0 mg, 3.0 mmol), Pd2(dba)3 (57.4 mg, 0.1 mmol), and t-BuONa (384.4 mg, 4.0 mmol) were added into the corresponding round-bottom flask. Next, toluene (30 ml), 4-(1,2,2-triphenylvinyl)aniline (347.5 mg, 1.0 mmol), and toluene solution of P(t-Bu)3 (2 ml) were added into the round-bottom flask. After that, the mixture was reuxed for 48 h and then cooled to room temperature. After completion of present reaction, the resulting mixture was extracted with dichloromethane and water, and then washed with brine three times. Organic layer was dried by anhydrous MgSO4, then the organic solvent was removed under vacuum, the residues were purified by column chromatography on silica gel with petroleum ether/dichloromethane (5:1) as eluent, affording the corresponding target product 1 (faint yellow solid), 2 (yellow solid) or 3 (light green solid) in a yield of 75.7%, 73.2% or 74.1%, respectively. 1: 1H NMR (500 MHz, CDCl3): δ (ppm) = 7.70 (d, J = 10 Hz, 2H), 7.64 (d, J = 10 Hz, 2H), 7.50 (d, J = 10 Hz, 2H), 7.35 (t, J = 7.5 Hz, 2H), 7.24 (s, 3H), 7.18-7.03 (m, 18H), 6.89-6.83 (m, 4H), 3.81 (s, 4H). 13C NMR (125 MHz, CDCl3): δ (ppm) = 146.8, 146.3, 144.5, 144.1, 143.8, 143.6, 143.0, 141.5, 140.7, 140.5, 137.7, 136.7, 132.2, 131.4, 131.4, 127.6, 127.6, 127.6, 126.8, 126.4, 126.3, 125.9, 124.9, 123.4, 122.5, 121.1, 120.3, 119.3, 36.9. EI-MS: m/z = 675.30[M]+. Anal. Calcd. For C52H37N: C, 92.41; H, 5.52, N, 2.07. Found: C, 92.50; H, 5.57; N, 2.01. 2: 1H NMR (500 MHz, CDCl3): δ (ppm) = 7.62 (d, J = 5 Hz, 2H), 7.56 (d, J = 10 Hz, 2H), 7.32-7.27 (m, 5H), 7.24-7.15 (m, 5H), 7.12-7.03 (m, 15H), 6.90-6.85 (m, 4H), 1.98-1.81 (m, 8H), 0.32 (t, J = 7.5 Hz, 12H). 13C NMR (125 MHz, CDCl3): δ (ppm) = 151.1, 149.7, 147.0, 146.3, 144.1, 143.8, 143.6, 141.3, 140.7, 140.4, 137.6, 136.4, 132.2, 131.4, 131.4, 127.6, 127.6, 126.8, 126.4, 126.4, 126.3, 126.2, 123.1, 122.7, 122.4, 120.1, 119.0, 118.9, 56.0, 32.7, 8.6. EI-MS: m/z = 787.40[M]+. Anal. Calcd. For C60H53N: C, 91.44; H, 6.78, N, 1.78. Found: C, 91.36; H, 6.85; N, 1.71. 3: 1H NMR (500 MHz, CDCl3): δ (ppm) = 7.61 (d, J = 5 Hz, 2H), 7.53 (d, J = 10 Hz, 2H), 7.30 (t, J = 5 Hz, 4H), 7.25 (s, 1H), 7.24-7.18 (m, 5H), 7.11-6.99 (m, 16H), 6.88 (s, 3H), 1.94-1.79 (m, 8H), 1.09-1.01 (m, 8H), 0.68-0.58 (m, 20H). 13C NMR (125 MHz, CDCl3): δ (ppm) = 151.9, 150.5, 146.8, 146.2, 144.1, 143.8, 143.6, 140.9, 140.8, 140.4, 137.7, 136.0, 132.1, 131.5, 131.4, 131.4, 127.6, 126.7, 126.5, 126.4, 126.3, 126.2, 123.0, 122.7, 122.4, 120.1, 119.0, 118.7, 54.9, 40.0, 26.0, 23.0, 13.9. EI-MS: m/z = 899.65[M]+. Anal. Calcd. For C68H69N: C, 90.72; H, 7.73, N, 1.56. Found: C, 90.79; H, 7.82; N, 1.51. |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

110K+ Compounds

110K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping