|

|

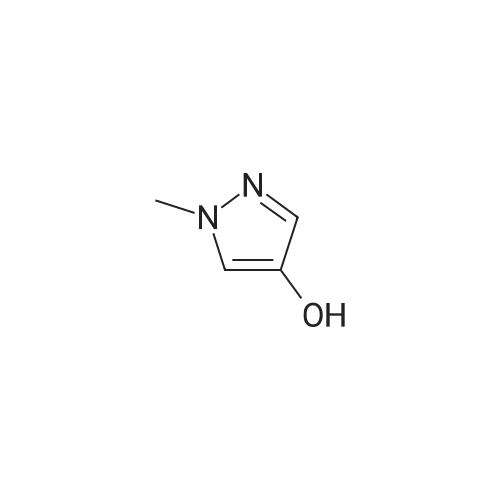

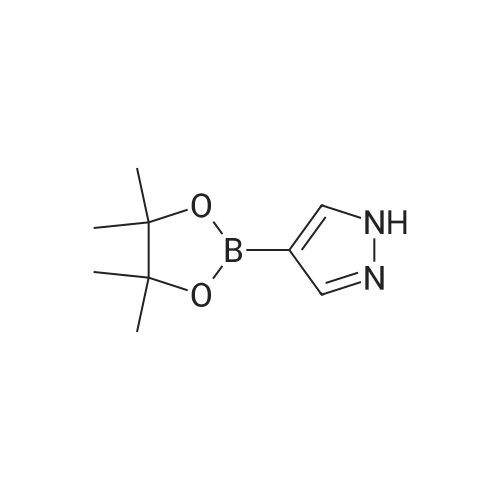

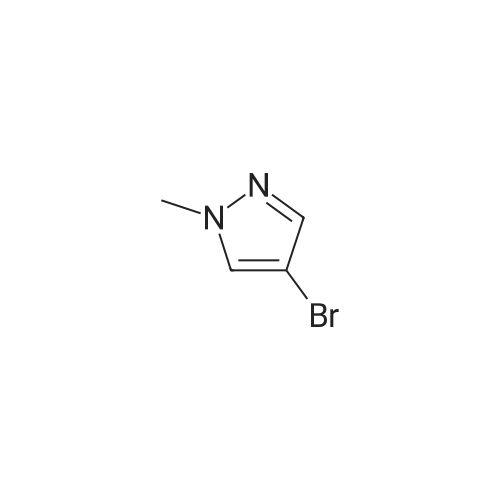

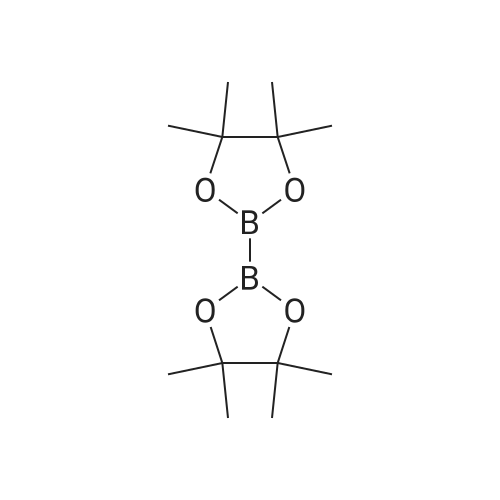

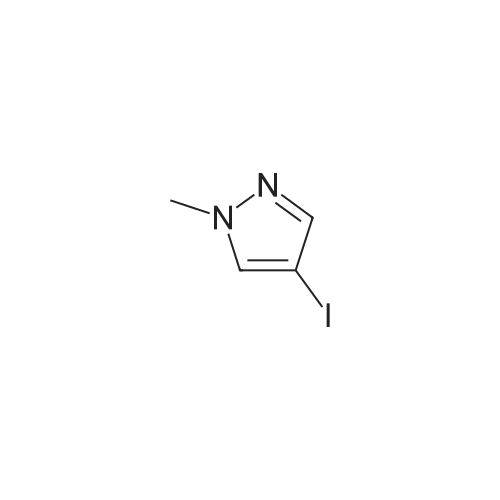

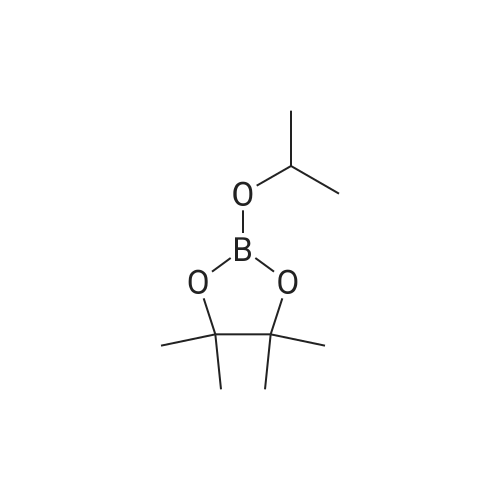

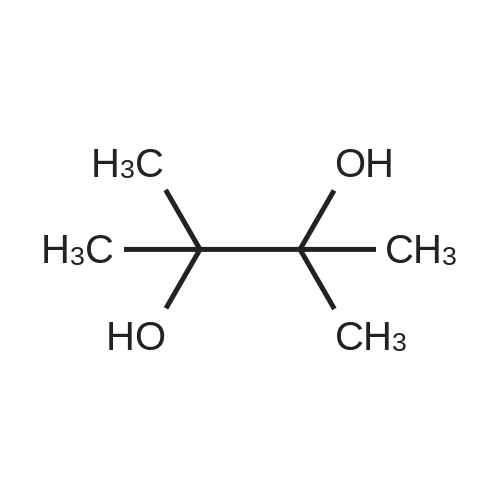

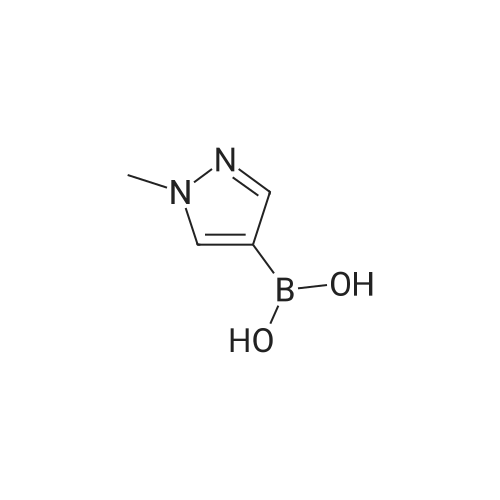

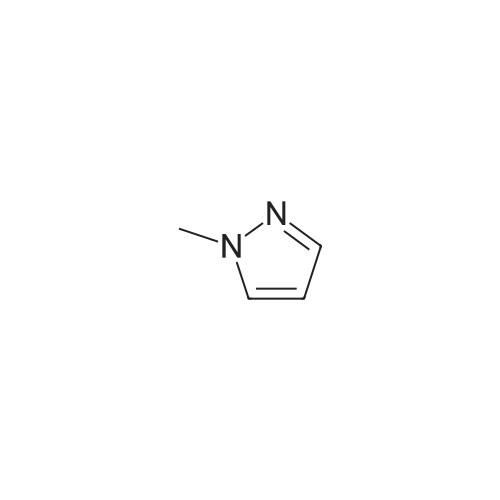

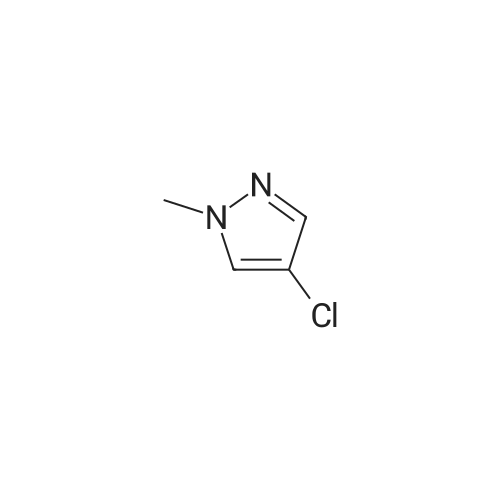

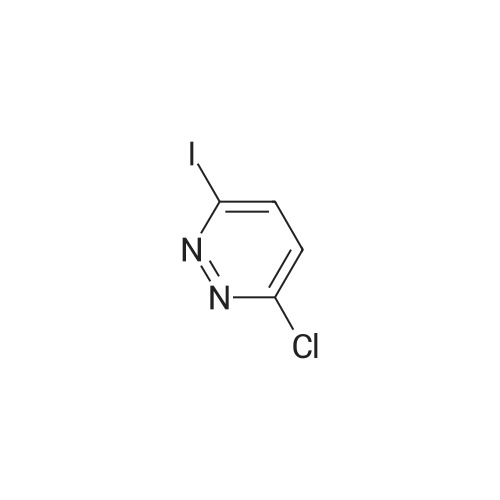

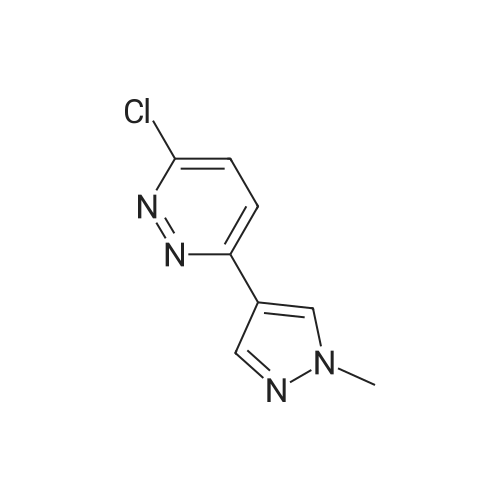

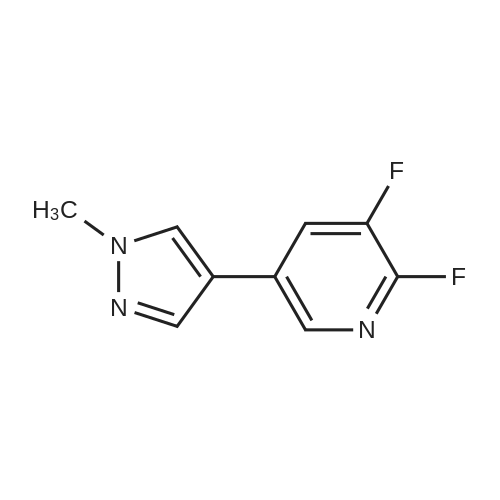

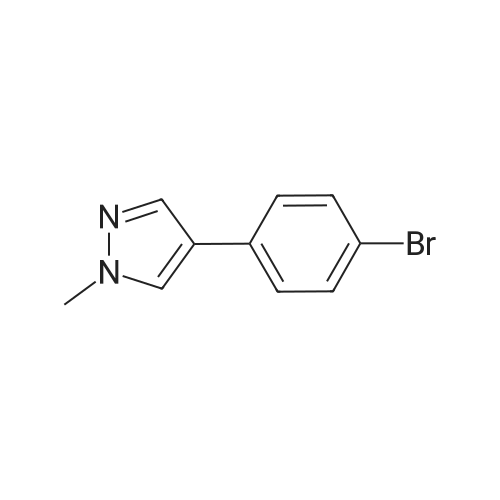

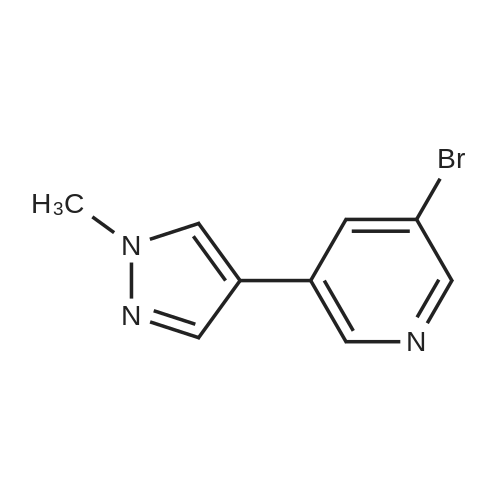

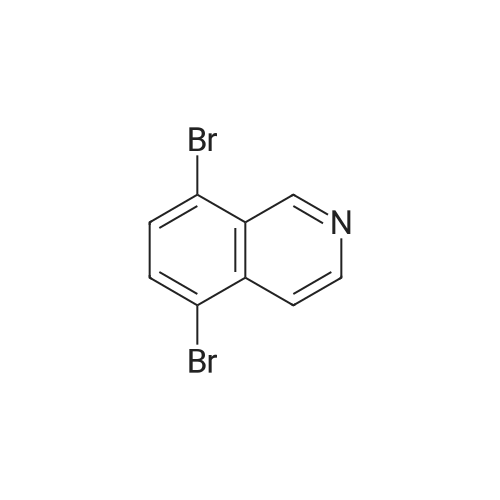

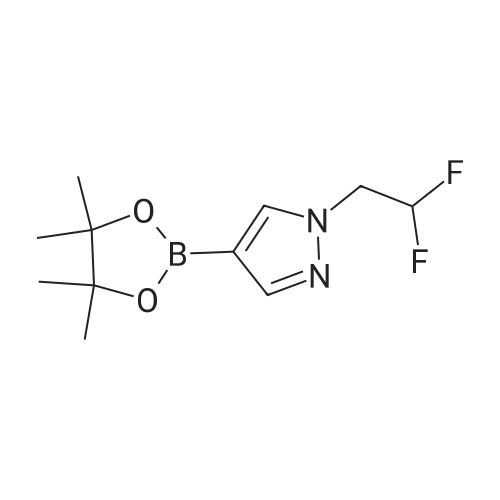

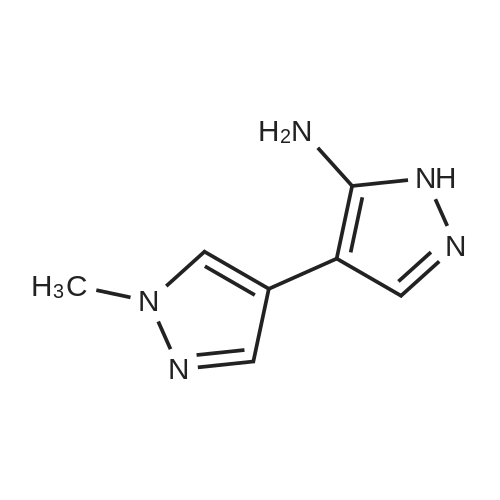

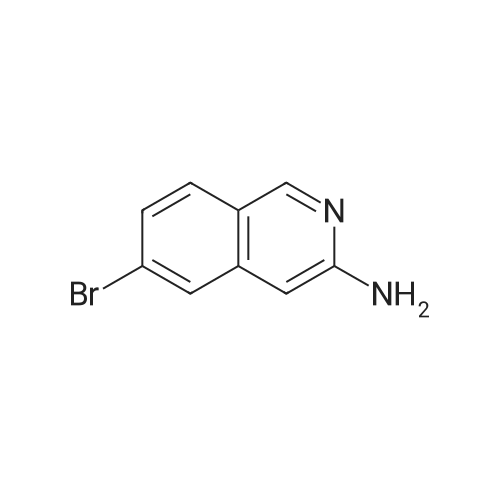

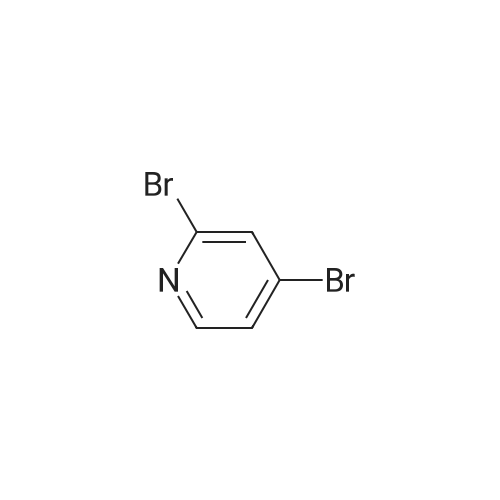

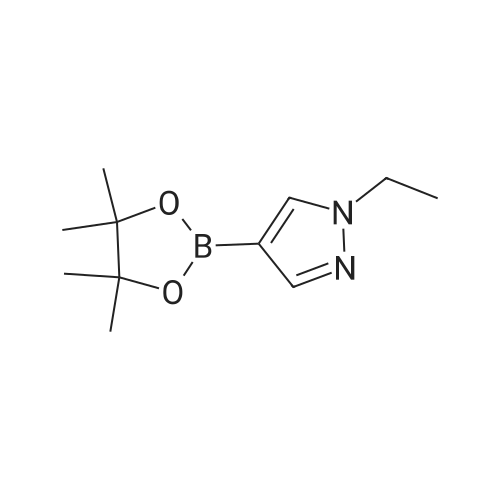

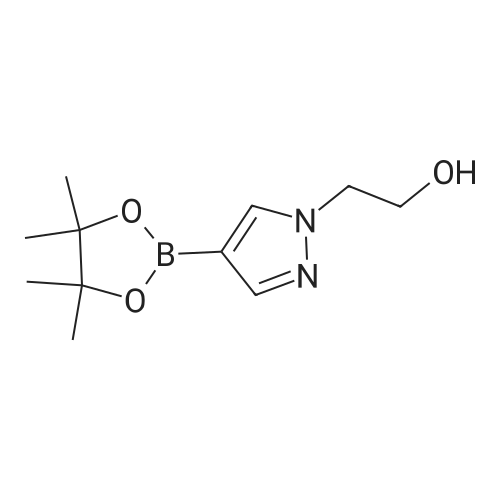

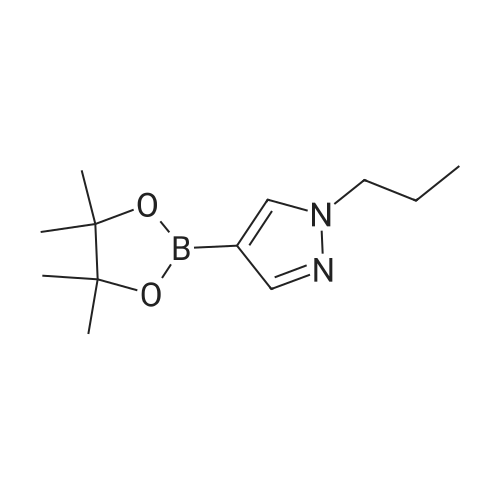

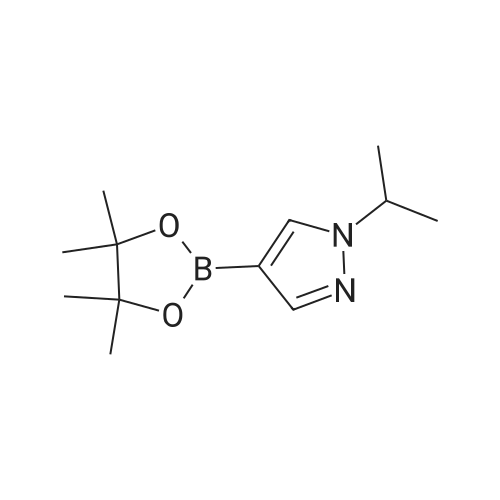

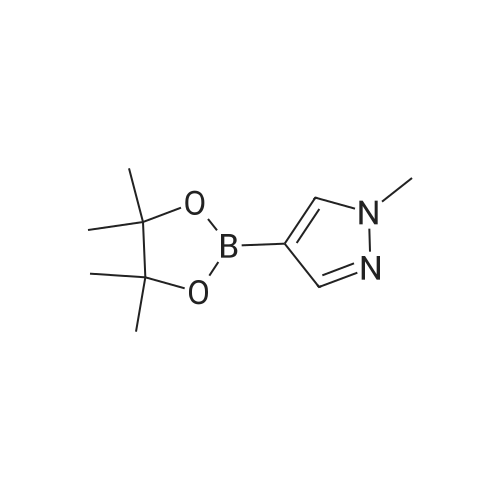

A suspension of 573 mg (2.0 mmol) <strong>[81045-39-8]5,8-dibromoisoquinoline</strong>, 458 mg (2.2 mmol) 1- methyM^^.S.S-tetramethyl-fl .S^ldioxaborolan^-y -I H-pyrazole, 849 mg (4.0 mmol) tri-potassium-phosphate trihydrate and 140 mg (0.20 mmol) bis- (triphenylphosphine)-palladium(ll)-chloride in 4 ml 1 ,2-dimethoxyethane were stirred for 18 hours at 80 C under nitrogen. The reaction mixture was cooled to room temperature, diluted with THF and filtered. The filtrate was evaporated and the residue was chromatographed on a silica gel column with ethylacetate/methanol as eluent. The two isomers were obtained separately.First eluted isomer: 8-bromo-5-(1-methyl-1 H-pyrazol-4-yl)-isoquinoline as colourless crystals; HPLC/MS 1.90 min, [M+H] = 288/290.Second eluted isomer: 5-bromo-8-(1-methyl-1 H-pyrazol-4-yl)-isoquinoline as yellow crystals; HPLC/MS (A) 2.02 min, [M+H] = 288/290.; A suspension of 135 mg (0.47 mmol) 8-bromo-5-(1-methyl-1H-pyrazol-4-yl)- isoquinoline, 126 mg (0.47 mmol) 2-(2-fluoro-phenyl)-[1,8]naphthyridine-4-boronic acid and 47.4 mg (0.56 mmol) sodium hydrogen carbonate in 1.2 ml DMF and 0.6 ml water was heated to 80 C under nitrogen. Then 6.6 mg (0.009 mmol) bis- (triphenylphosphine)-palladium(ll)-chloride were added. The reaction mixture was stirred for 18 hours at 80 C. The reaction mixture was cooled to room temperature and partitioned between water and dichloromethane. The organic phase was dried over sodium sulfate and evaporated. The residue was chromatographed on a silica gel column with ethyl acetate/methanol as eluent yielding 2-(2-fluoro-phenyl)-4-[5- (1-methyl-1H-pyrazol-4-yl)-isoquinolin-8-yl]-[1,8]naphthyridine as colourless solid; HPLC/MS (A): 1.87 min, [M+H] 432.1H NMR (400 MHz, DMSO) delta = 9.19 (dd, J=4.1, 1.9, 1H), 8.83 (d, J=0.9, 1H), 8.60 (d, J=6.0, 1H), 8.27 (s, 1H), 8.23 (td, J=7.9, 1.8, 1H), 8.17 (dd, J=6.0, 0.9, 1H), 8.11 (d, J=2A, 1H), 7.95 (d, J=7.4, 1H), 7.91 (m, 2H), 7.80 (d, J=7A, 1H), 7.62 (m, 1H), 7.57 (dd, J=8.4, 4.1, 1H), 7.47 (td, J=7.6, 1.1, 1H), 7.41 (ddd, J=11.6, 8.3, 1.0, 1H), 4.01 (s, 3H). Similarly was prepared: 2-(2-Fluoro-phenyl)-4-[8-(1-methyl-1H-pyrazol-4-yl)- isoquinolin-5-yl]-[1,8]naphthyridine as yellow solid; HPLC/MS (A): 1.84 min, [M+H] 432.1H NMR (400 MHz, DMSO) delta = 9.66 (d, J=0.9, 1H), 9.18 (dd, J=4.1, 1.9, 1H), 8.45 (d, J=5.9, 1H), 8.33 (s, 1H), 8.22 (td, J=7.9, 1.8, 1H), 8.06 (d, J=2.3, 1H), 7.95 (d, J=0.8, 1H), 7.93 (d, J=7.4, 1H), 7.87 (dd, J=8.4, 1.9, 1H), 7.83 (d, J=7.4, 1H), 7.62 (dddd, J=8.2, 7.2, 5.1, 1.9, 1H), 7.56 (dd, J=8A, 4.1, 1H), 7.47 (td, J=7.6, 1.1, 1H), 7.41 (ddd, .7=11.7, 8.3, 1.0, 1H), 7.29 (dd, .7=5.9, 0.9, 1H), 4.02 (s, 3H). |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

110K+ Compounds

110K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping