| 79% |

With (1,1'-bis(diphenylphosphino)ferrocene)palladium(II) dichloride; caesium carbonate In 1,4-dioxane; water at 80℃; for 18h; Inert atmosphere; |

150 Example 150N- { 3’- [(5aS,6S,9aR)-8-cyano-2,6-dimethyl-7-oxo-9a-phenyl-4,5,5 a,6,7,9a-hexahydro-2H- benzo [g] indazol-3 -yl]biphenyl-3 -yl} methanesulfonamide

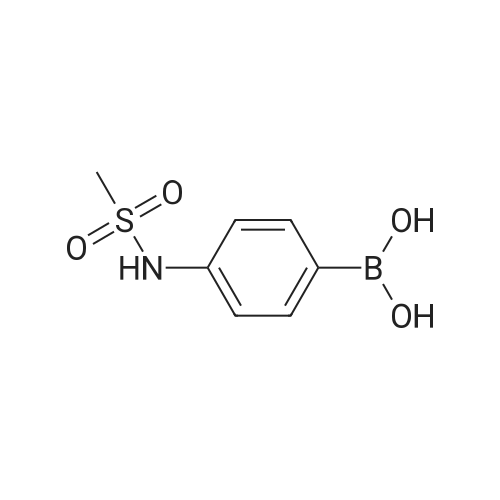

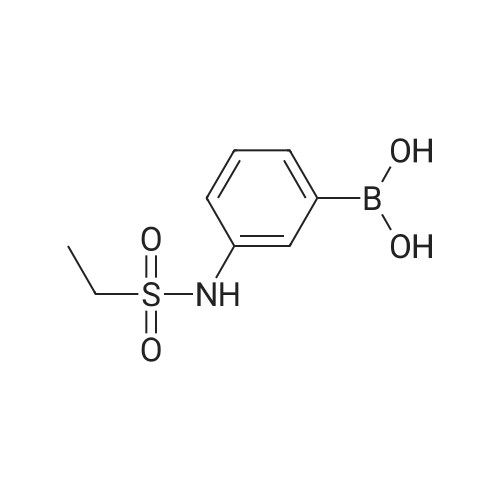

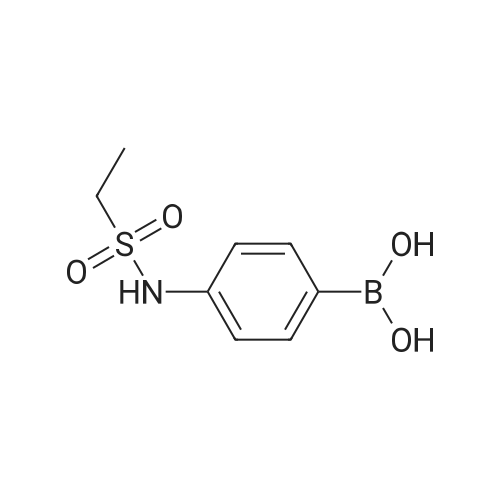

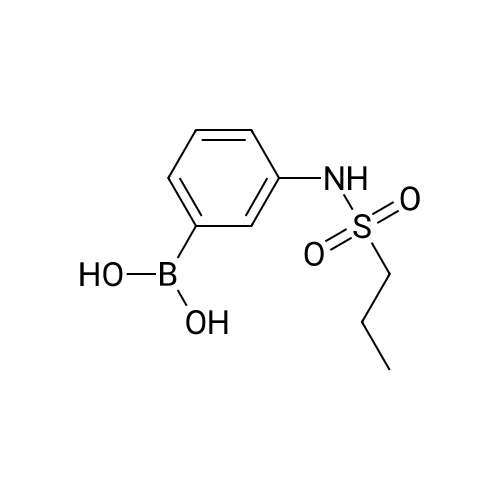

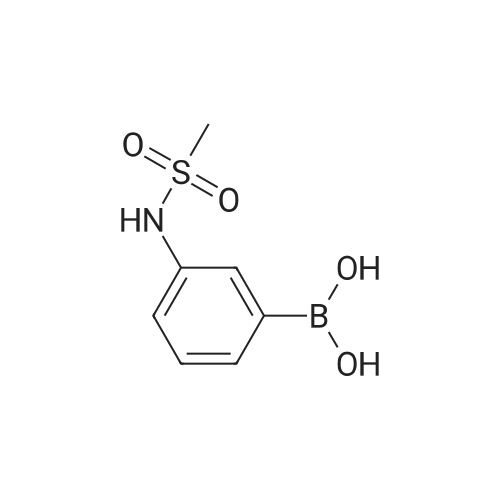

Example 150N- { 3’- [(5aS,6S,9aR)-8-cyano-2,6-dimethyl-7-oxo-9a-phenyl-4,5,5 a,6,7,9a-hexahydro-2H- benzo [g] indazol-3 -yl]biphenyl-3 -yl} methanesulfonamideExample 148D (0.05 g, 0.106 mmol), [1,1’-bis(diphenyl)phosphine)ferrocene] dichloropalladium(II) (0.0077 g, 0.0105 mmol), cesium carbonate (0.103 g, 0.318 mmol), and 3-(methylsulfonylamino)phenylboronic acid (0.068 g,0.318 mmol) were dissolved in dioxane (3 mL) and water (0.3 mL). Then nitrogen gas was bubbled through the mixture for 10 minutes followed by heating at 80 °C for 18 hours. After cooling to ambient temperature, 1 N aqueous ammonium chloride was added followed by extraction with ethyl acetate. The organic extracts were dried over anhydrous magnesium sulfate, filtered, and concentrated by rotary evaporation. The resultant residue was dissolvedin dichloromethane, and the solution was applied to a silica gel flash chromatography column eluted with 0% to 100% ethyl acetate in heptane to afford the titled compound (0.047 g, 79%). ‘HNMR(400 MHz, CDC13) ppm 8.51 (s, 1H), 7.63 (m, 3H), 7.47 (m, 4H), 7.32 (m, 3H), 7.22 (m, 1H), 6.99 (d, J=7.4 Hz, 2H), 6.47 (s, 1H), 3.87 (s, 3H), 3.08 (m, 3H), 2.79 (m, 2H), 2.43 (m, 2H), 1.83 (dd, J=13.6, 6.7 Hz, 1H), 1.57 (m, 1H), 1.17 (d, J=6.4 Hz, 3H); MS(ESI+) m/z 563 (M+H). |

| 79% |

With (1,1'-bis(diphenylphosphino)ferrocene)palladium(II) dichloride; caesium carbonate In 1,4-dioxane; water at 80℃; for 18h; Inert atmosphere; |

150 N-{3'-[(5aS,6S,9aR)-8-cyano-2,6-dimethyl-7-oxo-9a-phenyl-4,5,5a,6,7,9a-hexahydro-2H-benzo[g]indazol-3-yl]biphenyl-3-yl}methanesulfonamide

Example 148D (0.05 g, 0.106 mmol), [1,1′-bis(diphenyl)phosphine)ferrocene]dichloropalladium(II) (0.0077 g, 0.0105 mmol), cesium carbonate (0.103 g, 0.318 mmol), and 3-(methylsulfonylamino)phenylboronic acid (0.068 g, 0.318 mmol) were dissolved in dioxane (3 mL) and water (0.3 mL). Then nitrogen gas was bubbled through the mixture for 10 minutes followed by heating at 80° C. for 18 hours. After cooling to ambient temperature, 1 N aqueous ammonium chloride was added followed by extraction with ethyl acetate. The organic extracts were dried over anhydrous magnesium sulfate, filtered, and concentrated by rotary evaporation. The resultant residue was dissolved in dichloromethane, and the solution was applied to a silica gel flash chromatography column eluted with 0% to 100% ethyl acetate in heptane to afford the titled compound (0.047 g, 79%). 1H NMR (400 MHz, CDCl3) δ ppm 8.51 (s, 1H), 7.63 (m, 3H), 7.47 (m, 4H), 7.32 (m, 3H), 7.22 (m, 1H), 6.99 (d, J=7.4 Hz, 2H), 6.47 (s, 1H), 3.87 (s, 3H), 3.08 (m, 3H), 2.79 (m, 2H), 2.43 (m, 2H), 1.83 (dd, J=13.6, 6.7 Hz, 1H), 1.57 (m, 1H), 1.17 (d, J=6.4 Hz, 3H); MS (ESI+) m/z 563 (M+H)+. |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

110K+ Compounds

110K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping