| 40% |

|

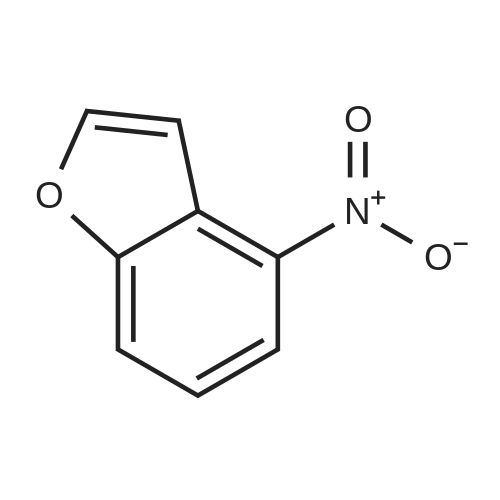

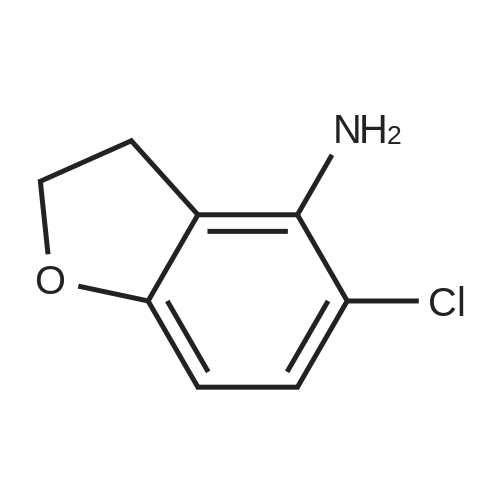

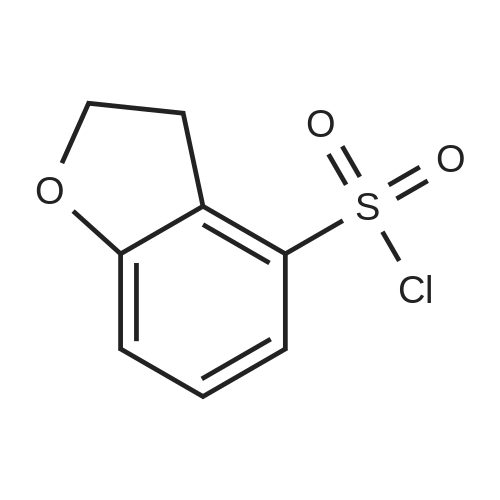

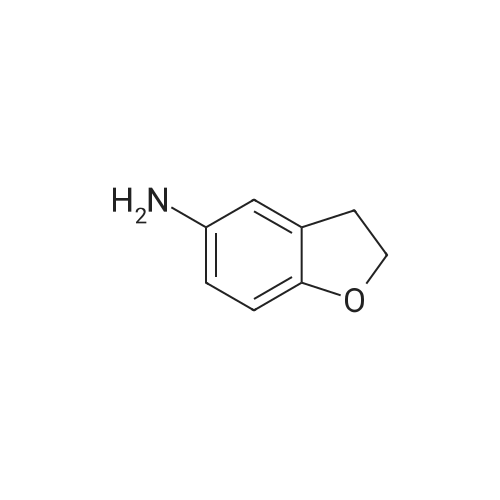

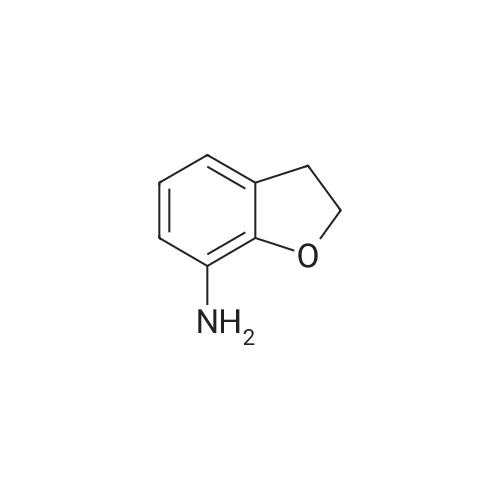

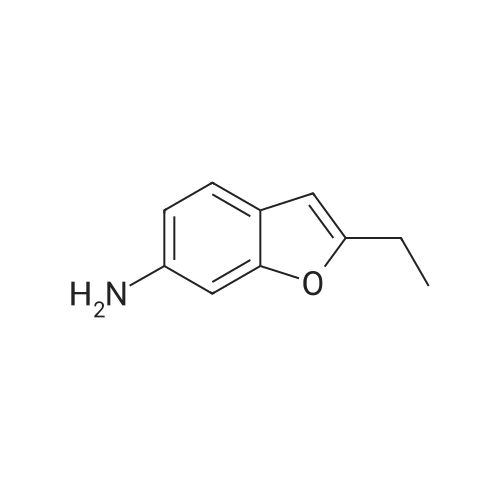

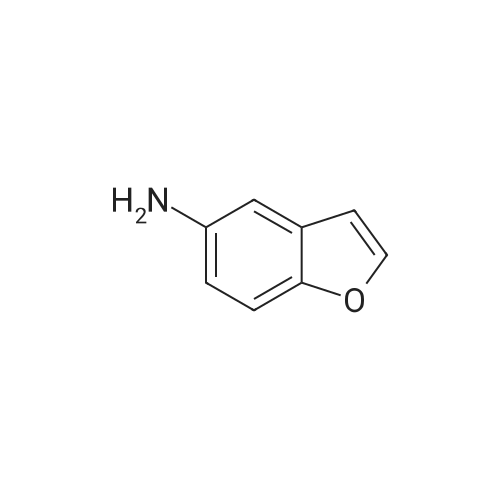

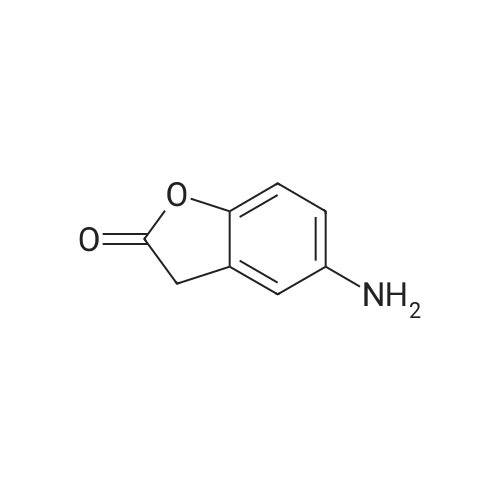

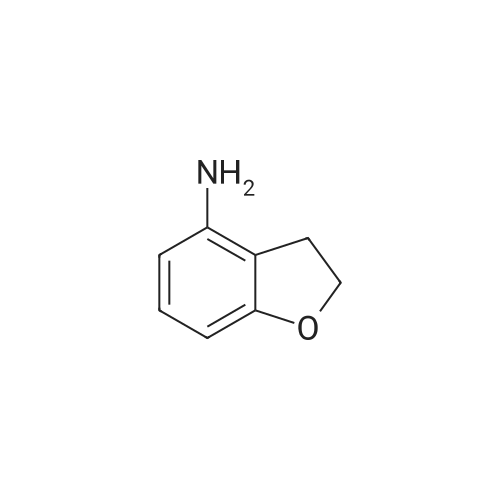

5. Synthesis of 2,3-dihydrobenzofuran-4-sulfonyl chloride; Hydrochloric acid (9.0 g) was added dropwise to a solution of <strong>[61090-37-7]2,3-dihydrobenzofuran-4-amine</strong> (16.3 mmol) and acetic acid (9.0 g) in acetonitrile (200 mL) at 0 C. A solution of sodium nitrite (22.0 mmol) in water (2 mL) was subsequently added and the mixture was maintained for 30 min at 0 C. Sulfur dioxide gas was passed through the reaction mixture for 2 h whereupon a solution of copper(II) chloride dihydrate (20.0 mmol) in water (3 mL) was added. Sulfur dioxide gas was passed through the reaction mixture for an additional 2 h. The reaction mixture was allowed to warm to rt and was maintained for 16 h. The reaction mixture was diluted with ice water (200 mL) and the resulting mixture was extracted with ethyl acetate (300 mL). The organic layer was washed with water (200 mL), dried (sodium sulfate), and concentrated. The residue was purified by Flash chromatography (1/70 ethyl acetate/petroleum ether) to provide 2,3-dihydrobenzofuran-4-sulfonyl chloride in 40% yield as a yellow solid. Data: 1H NMR (CDCl3) delta 7.40 (d, 1H), 7.30 (d, 1H), 7.10 (d, 1H), 4.70 (m, 2H), 3.60 (m, 2H). LC/MS (ES) m/z 283 [M+C5H11N2-Cl+H]+. |

| 40% |

|

5. Synthesis of 2,3-dihvdrobenzofuran-4-sulfonyl chloride.Hydrochloric acid (9.0 g) was added dropwise to a solution of 2,3-dihydrobenzofuran-4- amine (16.3 mmol) and acetic acid (9.0 g) in acetonitrile (200 mL) at 0 0C. A solution of sodium nitrite (22.0 mmol) in water (2 mL) was subsequently added and the mixture was maintained for 30 min at 0 0C. Sulfur dioxide gas was passed through the reaction mixture for 2 h whereupon a solution of copper(II) chloride dihydrate (20.0 mmol) in water (3 mL) was added. Sulfur dioxide gas was passed through the reaction mixture for an additional 2 h. The reaction mixture was allowed to warm to rt and was maintained for 16 h. The reaction mixture was diluted with ice water (200 mL) and the resulting mixture was extracted with ethyl acetate (300 mL). The organic layer was washed with water (200 mL), dried (sodium sulfate), and concentrated. The residue was purified by Flash chromatography (1/70 ethyl acetate/petroleum ether) to provide 2,3-dihydrobenzofuran-4-sulfonyl chloride in 40% yield as a yellow solid. Data: 1H NMR (CDCl3) delta 7.40 (d, IH), 7.30 (d, IH), 7.10 (d, IH), 4.70 (m, 2H), 3.60 (m, 2H). LC/MS (ES) m/z 283 [M+C5H11N2-C1+H]+. |

| 40% |

With hydrogenchloride; copper(II) choride dihydrate; sulfur dioxide; acetic acid; sodium nitrite; In water; acetonitrile; |

Hydrochloric acid (9.0 g) was added dropwise to a solution of <strong>[61090-37-7]2,3-dihydrobenzofuran-4-amine</strong> (16.3 mmol) and acetic acid (9.0 g) in acetonitrile (200 mL) at 0 C. A solution of sodium nitrite (22.0 mmol) in water (2 mL) was subsequently added and the mixture was maintained for 30 min at 0 C. Sulfur dioxide gas was passed through the reaction mixture for 2 h whereupon a solution of copper(II) chloride dihydrate (20.0 mmol) in water (3 mL) was added. Sulfur dioxide gas was passed through the reaction mixture for an additional 2 h. The reaction mixture was allowed to warm to rt and was maintained for 16 h. The reaction mixture was diluted with ice water (200 mL) and the resulting mixture was extracted with ethyl acetate (300 mL). The organic layer was washed with water (200 mL), dried (sodium sulfate), and concentrated. The residue was purified by Flash chromatography (1/70 ethyl acetate/petroleum ether) to provide 2,3-dihydrobenzofuran-4-sulfonyl chloride in 40% yield as a yellow solid. Data: 1H NMR (CDCl3) delta 7.40 (d, 1H), 7.30 (d, 1H), 7.10 (d, 1H), 4.70 (m, 2H), 3.60 (m, 2H). LC/MS (ES) ml/283 [M+C5H11N2-Cl+H]+. |

| 40% |

|

5. Synthesis of 2,3-dihydrobenzofuran-4-sulfonyl chloride.Hydrochloric acid (9.0 g) was added dropwise to a solution of 2,3-dihydrobenzofuran-4- amine (16.3 mmol) and acetic acid (9.0 g) in acetonitrile (200 mL) at 0 0C. A solution of sodium nitrite (22.0 mmol) in water (2 mL) was subsequently added and the mixture was maintained for 30 min at 0 0C. Sulfur dioxide gas was passed through the reaction mixture for 2 h whereupon a solution of copper(II) chloride dihydrate (20.0 mmol) in water (3 mL) was added. Sulfur dioxide gas was passed through the reaction mixture for an additional 2 h. The reaction mixture was allowed to warm to rt and was maintained for 16 h. The reaction mixture was diluted with ice water (200 mL) and the resulting mixture was extracted with ethyl acetate (300 mL). The organic layer was washed with water (200 mL), dried (sodium sulfate), and concentrated. The residue was purified by Flash chromatography (1/70 ethyl acetate/petroleum ether) to provide 2,3-dihydrobenzofuran-4-sulfonyl chloride in 40% yield as a yellow solid. Data: 1H NMR (CDCl3) delta 7.40 (d, IH), 7.30 (d, IH), 7.10 (d, IH), 4.70 (m, 2H), 3.60 (m, 2H). LC/MS (ES) m/z 283 [M+C5H11N2-C1+H]+. |

| 40% |

|

Hydrochloric acid (9.0 g) was added dropwise to a solution of <strong>[61090-37-7]2,3-dihydrobenzofuran-4-amine</strong> (16.3 mmol) and acetic acid (9.0 g) in acetonitrile (200 mL) at 0 C. A solution of sodium nitrite (22.0 mmol) in water (2 mL) was subsequently added and the mixture was maintained for 30 min at 0 C. Sulfur dioxide gas was passed through the reaction mixture for 2 h whereupon a solution of copper(II) chloride dihydrate (20.0 mmol) in water (3 mL) was added. Sulfur dioxide gas was passed through the reaction mixture for an additional 2 h. The reaction mixture was allowed to warm to rt and was maintained for 16 h. The reaction mixture was diluted with ice water (200 mL) and the resulting mixture was extracted with ethyl acetate (300 mL). The organic layer was washed with water (200 mL), dried (sodium sulfate), and concentrated. The residue was purified by Flash chromatography (1/70 ethyl acetate/petroleum ether) to provide 2,3-dihydrobenzofuran-4-sulfonyl chloride in 40% yield as a yellow solid. Data: 1H NMR (CDCl3) delta 7.40 (d, 1H), 7.30 (d, 1H), 7.10 (d, 1H), 4.70 (m, 2H), 3.60 (m, 2H). LC/MS (ES) m/z 283 [M+C5H11N2-Cl+H]+. |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

110K+ Compounds

110K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping