| 11% |

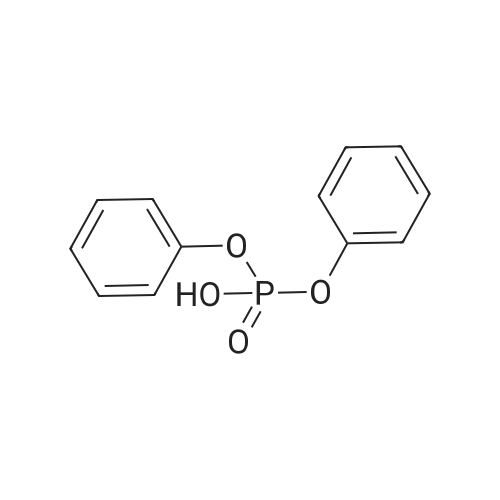

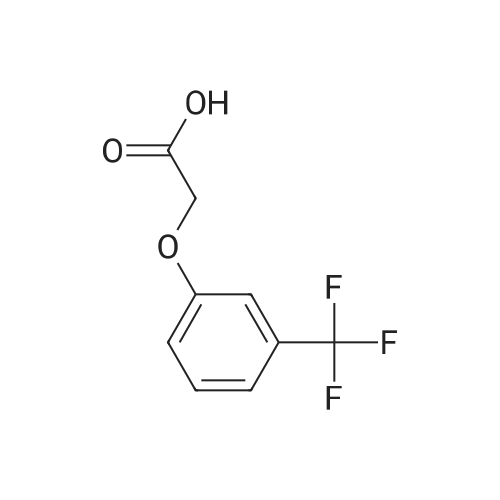

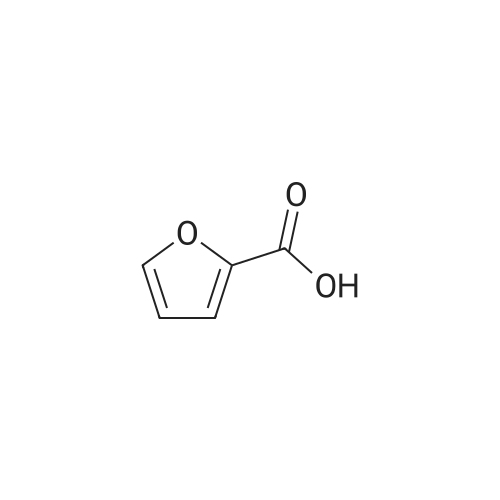

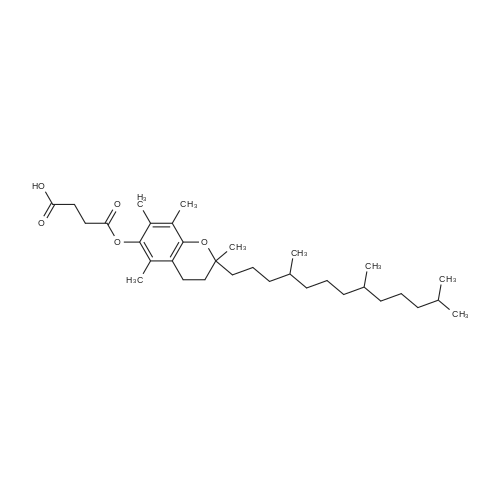

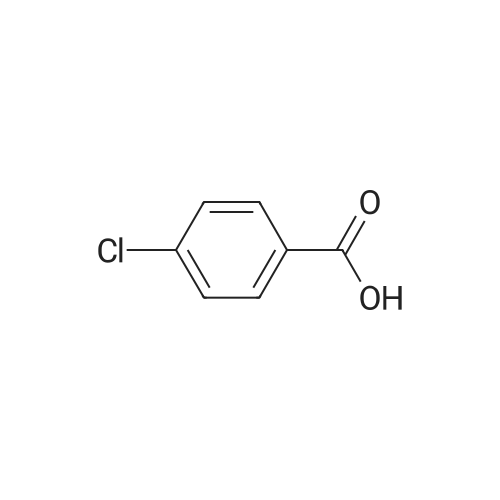

With dmap; N-[3-(N,N-dimethylamino)-propyl]-N'-ethyl-carbodiimide hydrochloride In dichloromethane at 45℃; |

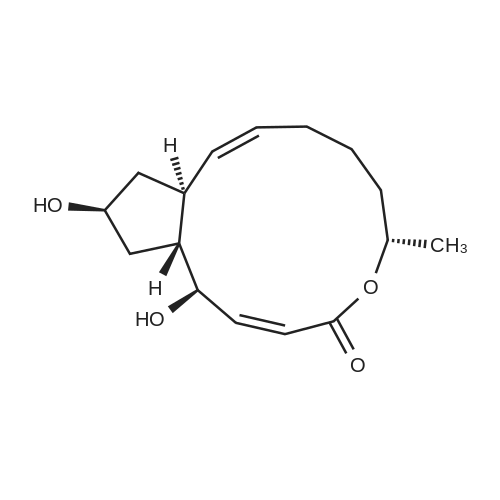

3.4. General Synthetic Methods for Compounds 2-16

General procedure: Benzoic acid-derived reagent (1-2 equivalent) was added to a solution of 1 (50.0 mg,0.18 mmol), DMAP (21.8 mg, 0.18 mmol), and EDCl (110.7 mg, 0.71 mmol) in 15 mL drydichloromethane (DCM). The reaction mixture was stirred at 45 °C, and the progress ofthe reaction was monitored by silica gel TLC and UPLC-MS. After 1-3 h, the reactionmixture was quenched with water and diluted with DCM. The organic layer was separated,and the solvent was removed under reduced pressure. The residue was purified bysilica gel CC followed by semi-preparative HPLC to yield unreacted 1 and derivatives 2-16 (Figures S4-S48).Brefeldin A 7-O-benzoate (2): Known compound. Colorless oil; yield 11%; 1H NMR(400 MHz, CDCl3) δ 8.03-7.98 (2H, overlapped), 7.56 (1H, m), 7.47-7.43 (2H, overlapped),7.37 (1H, dd, J = 15.7, 3.1 Hz), 5.94 (1H, dd, J = 15.7, 1.9 Hz), 5.73 (1H, m), 5.40 (1H, m), 5.26(1H, dd, J = 15.2, 9.0 Hz), 4.86 (1H, m), 4.17 (1H, m), 2.53-2.33 (3H, overlapped), 2.06-1.96(2H, overlapped), 1.92 (1H, m), 1.88-1.80 (2H, overlapped), 1.77-1.70 (2H, overlapped),1.53 (1H, m), 1.26 (3H, d, J = 6.2 Hz), 0.96 (1H, m); 13C NMR (100 MHz, CDCl3) δ 166.3 (C =O), 166.3 (C = O), 151.6 (CH), 136.1 (CH), 133.1 (CH), 131.1 (CH), 130.6 (C), 129.7 (CH × 2),128.5 (CH × 2), 117.9 (CH), 76.1 (CH), 76.0 (CH), 71.9 (CH), 52.6 (CH), 44.1 (CH), 40.3(CH2), 38.9 (CH2), 34.2 (CH2), 32.0 (CH2), 26.8 (CH2), 21.0 (CH3). ESIMS m/z 407.4 [M +Na]+. |

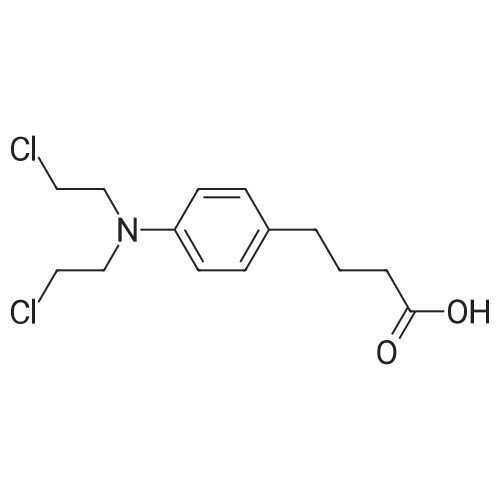

| 11% |

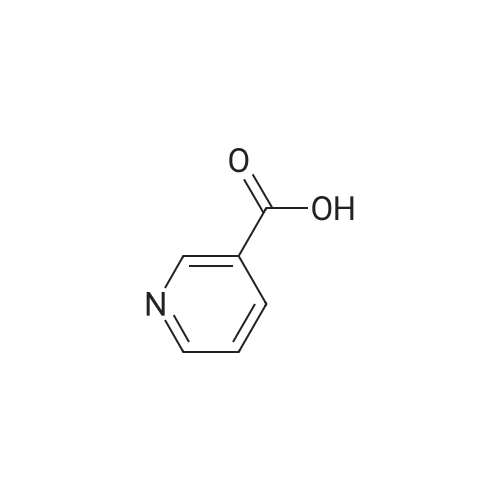

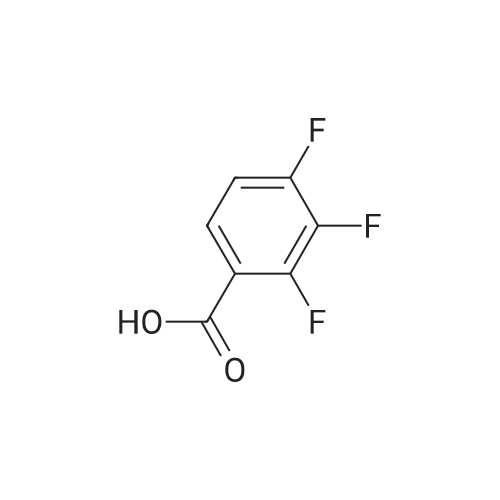

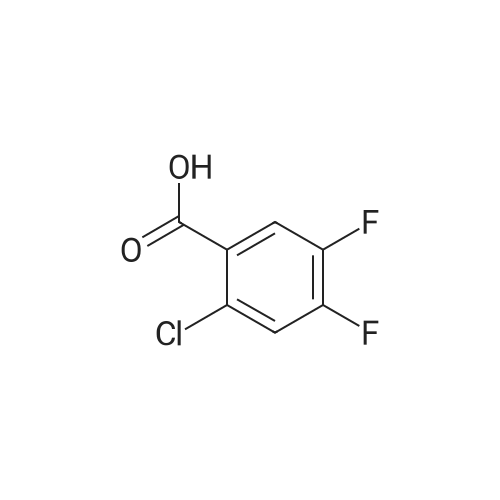

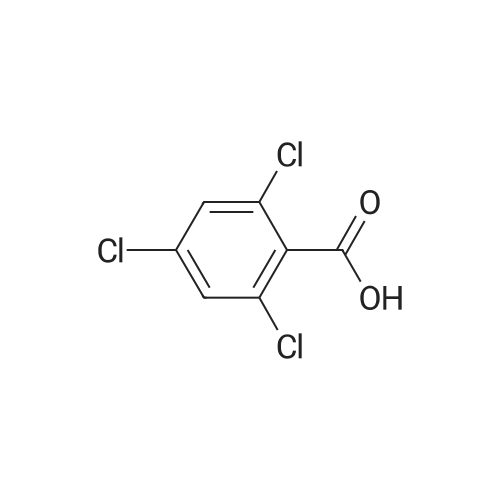

With dmap; N-[3-(N,N-dimethylamino)-propyl]-N'-ethyl-carbodiimide hydrochloride In dichloromethane at 45℃; |

3.4. General Synthetic Methods for Compounds 2-16

General procedure: Benzoic acid-derived reagent (1-2 equivalent) was added to a solution of 1 (50.0 mg,0.18 mmol), DMAP (21.8 mg, 0.18 mmol), and EDCl (110.7 mg, 0.71 mmol) in 15 mL drydichloromethane (DCM). The reaction mixture was stirred at 45 °C, and the progress ofthe reaction was monitored by silica gel TLC and UPLC-MS. After 1-3 h, the reactionmixture was quenched with water and diluted with DCM. The organic layer was separated,and the solvent was removed under reduced pressure. The residue was purified bysilica gel CC followed by semi-preparative HPLC to yield unreacted 1 and derivatives 2-16 (Figures S4-S48).Brefeldin A 7-O-benzoate (2): Known compound. Colorless oil; yield 11%; 1H NMR(400 MHz, CDCl3) δ 8.03-7.98 (2H, overlapped), 7.56 (1H, m), 7.47-7.43 (2H, overlapped),7.37 (1H, dd, J = 15.7, 3.1 Hz), 5.94 (1H, dd, J = 15.7, 1.9 Hz), 5.73 (1H, m), 5.40 (1H, m), 5.26(1H, dd, J = 15.2, 9.0 Hz), 4.86 (1H, m), 4.17 (1H, m), 2.53-2.33 (3H, overlapped), 2.06-1.96(2H, overlapped), 1.92 (1H, m), 1.88-1.80 (2H, overlapped), 1.77-1.70 (2H, overlapped),1.53 (1H, m), 1.26 (3H, d, J = 6.2 Hz), 0.96 (1H, m); 13C NMR (100 MHz, CDCl3) δ 166.3 (C =O), 166.3 (C = O), 151.6 (CH), 136.1 (CH), 133.1 (CH), 131.1 (CH), 130.6 (C), 129.7 (CH × 2),128.5 (CH × 2), 117.9 (CH), 76.1 (CH), 76.0 (CH), 71.9 (CH), 52.6 (CH), 44.1 (CH), 40.3(CH2), 38.9 (CH2), 34.2 (CH2), 32.0 (CH2), 26.8 (CH2), 21.0 (CH3). ESIMS m/z 407.4 [M +Na]+. |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

HazMat Fee +

HazMat Fee +

For Research Only

For Research Only

110K+ Compounds

110K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping