| 14 mg; 15 mg |

With toluene-4-sulfonic acid; In tetrahydrofuran; at 0 - 25℃; for 3.5h;Inert atmosphere; |

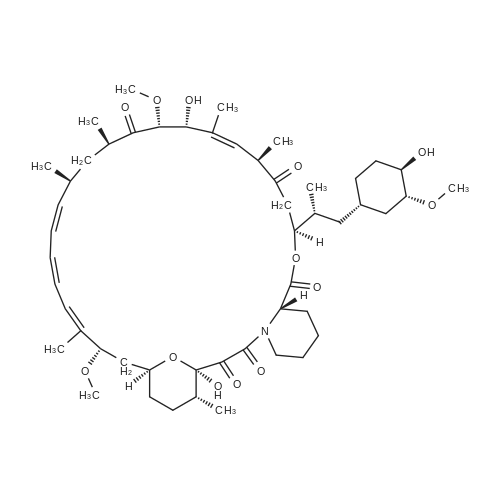

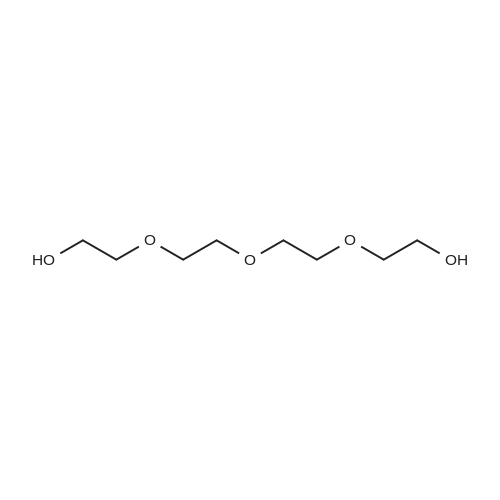

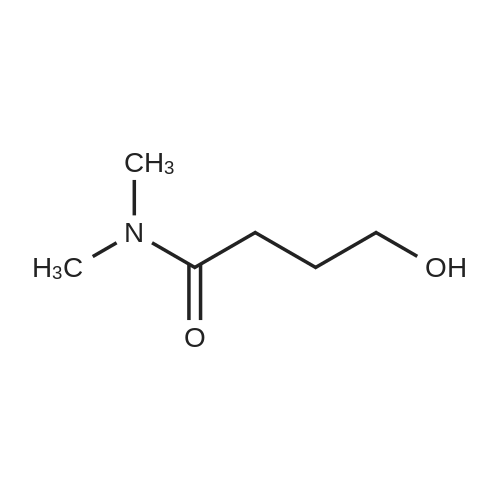

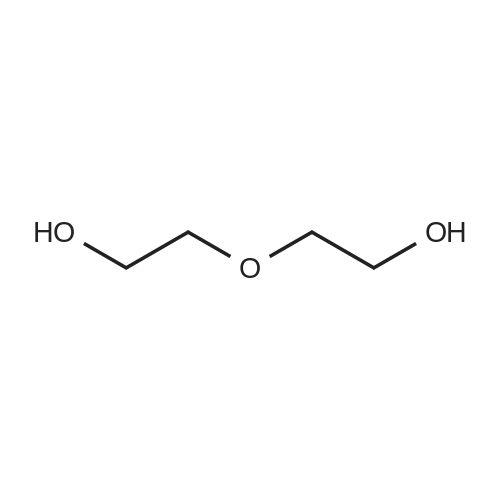

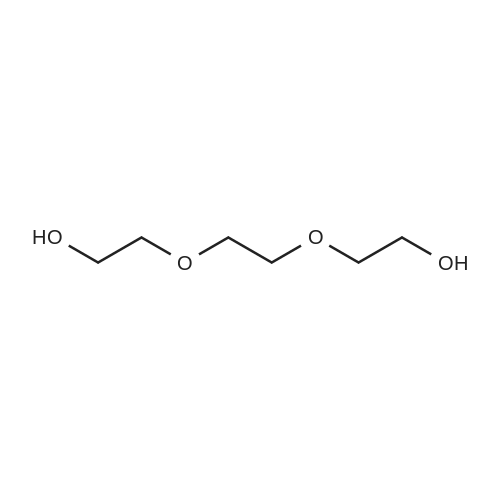

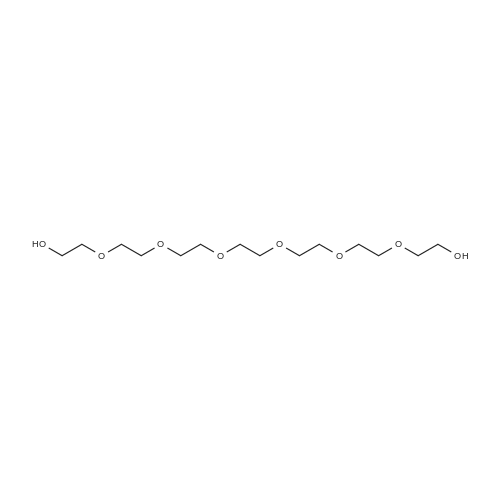

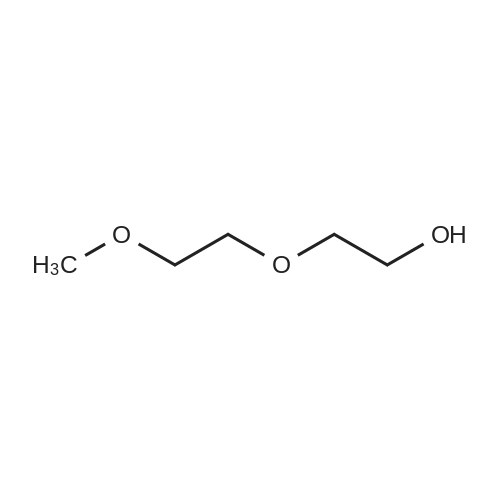

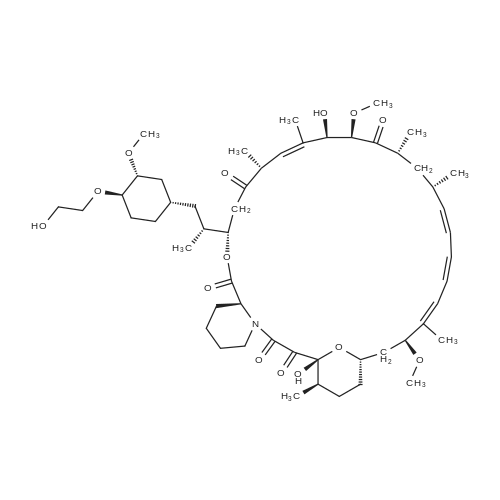

A solution of <strong>[159351-69-6]everolimus</strong> (1 g, 1.04 mmol) in THF (15 mL) was degassed with N2. p-toluenesulfonic acid (0.895 g, 5.20 mmol) was added at 0 C followed by 2-(2- hydroxyethoxy)ethanol (2.8 mL). The resulting mixture was stirred at 0C for 0.5 h under N2, then at 25C for 3 h. The reaction was poured into sat.NaHCO3 (40 mL), extracted with EtOAc (30 mL), washed with water (30 mL × 2) and brine (40 mL) then dried over anhydrous Na2SO4, filtered and concentrated. The resulting residue was purified by normal phase silica gel chromatography (MeOH: DCM = 1:15) then reverse-phase chromatography (C18, CH3CN: H2O= 7: 3) to obtain (21E,23E,25E,26E,34R,35S,36R,37R,39S,41S,44S,45R,46R,55R)- 45,55-dihydroxy-43-[2-(2-hydroxyethoxy)ethoxy]-44-[(1R)-2-[(1S,3R,4R)-4-(2- hydroxyethoxy)-3-methoxy-cyclohexyl]-1-methyl-ethyl]-46-methoxy-34,35,36,37,47,48- hexamethyl-66,67-dioxa-56-azatricyclohexatriaconta-21,23,25(47),26(48)-tetraene- 49,50,51,52,53-pentone (0.43 g, 40% yield) as a light yellow solid. ESI-MS (EI+, m/z):1053.9 [M+Na]+. 1H NMR (400 MHz, CDCl3) d6.47- 5.85 (m, 4H), 5.40 (ddd, J = 99.7, 51.9, 29.1 Hz, 4H), 4.80 (d, J = 22.0 Hz, 1H), 4.23 (d, J = 42.5 Hz, 1H), 4.05- 3.54 (m, 13H), 3.52- 3.01 (m, 14H), 2.67 (ddd, J = 46.8, 27.3, 6.8 Hz, 4H), 2.17 (dd, J = 82.0, 45.9 Hz, 6H), 1.70 (dt, J = 21.0, 15.8 Hz, 12H), 1.34 (dd, J = 105.2, 26.3 Hz, 11H), 1.15- 0.79 (m, 18H), 0.76- 0.64 (m, 1H). 90 mg of (21E,23E,25E,26E,34R,35S,36R,37R,39S,41S,44S,45R,46R,55R)- 45,55-dihydroxy-43-[2-(2-hydroxyethoxy)ethoxy]-44-[(1R)-2-[(1S,3R,4R)-4-(2- hydroxyethoxy)-3-methoxy-cyclohexyl]-1-methyl-ethyl]-46-methoxy-34,35,36,37,47,48- hexamethyl-66,67-dioxa-56-azatricyclohexatriaconta-21,23,25(47),26(48)-tetraene- 49,50,51,52,53-pentone was purified via prep chiral HPLC and the resulting epimers were obtained: (21E,23E,25E,26E,34R,35S,36R,37R,39S,41S,43R,44S,45R,46R,55R)-45,55- dihydroxy-43-[2-(2-hydroxyethoxy)ethoxy]-44-[(1R)-2-[(1S,3R,4R)-4-(2-hydroxyethoxy)-3- methoxy-cyclohexyl]-1-methyl-ethyl]-46-methoxy-34,35,36,37,47,48-hexamethyl-66,67- dioxa-56-azatricyclohexatriaconta-21,23,25(47),26(48)-tetraene-49,50,51,52,53-pentone (I- 116: 14 mg, 16% yield) and (21E,23E,25E,26E,34R,35S,36R,37R,39S,41S,43S,44S,45R,46R,55R)-45,55-dihydroxy-43- [2-(2-hydroxyethoxy)ethoxy]-44-[(1R)-2-[(1S,3R,4R)-4-(2-hydroxyethoxy)-3-methoxy- cyclohexyl]-1-methyl-ethyl]-46-methoxy-34,35,36,37,47,48-hexamethyl-66,67-dioxa-56- azatricyclohexatriaconta-21,23,25(47),26(48)-tetraene-49,50,51,52,53-pentone (I-117: 15 mg, 17% yield), both as white solids. The chiral separation method is listed below: I-116: ESI-MS (EI+, m/z):1054.0 [M+Na]+. 1H NMR (500 MHz, , CDCl3) d 6.42 - 5.90 (m, 4H), 5.79 (ddd, J = 51.6, 30.9, 16.6 Hz, 1H), 5.54- 5.08 (m, 4H), 5.03- 4.88 (m, 1H), 4.74 (d, J = 61.6 Hz, 1H), 4.28 (dd, J = 57.6, 29.0 Hz, 2H), 3.99 (dd, J = 26.5, 6.0 Hz, 1H), 3.89- 3.55 (m, 12H), 3.54- 2.96 (m, 15H), 2.87- 2.47 (m, 4H), 2.38- 1.92 (m, 8H), 1.86- 1.67 (m, 11H), 1.51- 1.30 (m, 6 H), 1.14- 0.80 (m, 18H), 0.76- 0.64 (m, 1H). I-117: ESI-MS (EI+, m/z):1053.9 [M+Na]+. 1H NMR (500 MHz, , CDCl3) d 6.41 - 6.22 (m, 2H), 6.13 (dd, J = 15.1, 10.1 Hz, 1H), 5.94 (dd, J = 22.3, 10.8 Hz, 1H), 5.52 (dt, J = 18.4, 9.2 Hz, 1H), 5.41 (d, J = 9.9 Hz, 1H), 5.27 (d, J = 5.3 Hz, 1H), 5.12 (dt, J = 46.3, 5.6 Hz, 1H), 4.83 (s, 1H), 4.23- 4.14 (m, 1H), 3.91- 3.52 (m, 15H), 3.49- 3.25 (m, 12H), 3.23 - 3.03 (m, 3H), 2.94- 2.80 (m, 1H), 2.65 (ddd, J = 23.4, 16.9, 6.0 Hz, 3H), 2.39- 2.15 (m, 2H), 2.16- 1.85 (m, 5H), 1.82- 1.64 (m, 10H), 1.47 (dd, J = 26.8, 15.9 Hz, 5H), 1.38- 1.16 (m, 6H), 1.10 (d, J = 6.8 Hz, 3H), 1.07- 1.03 (m, 3H), 1.00 (t, J = 6.8 Hz, 3H), 0.94 (d, J = 6.6 Hz, 3H), 0.88 (ddd, J = 34.0, 16.9, 5.0 Hz, 6H), 0.71 (dd, J = 23.9, 11.8 Hz, 1H). |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

110K+ Compounds

110K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping